In terms of hand speed, how fast can the flexible gripper be?

Have not used flexible claw partners, often have a question, flexible claw, how fast can the fastest?

Why can flexible jaws achieve such high hand speeds?

Pneumatic VS electric

Image from the Internet

The electric gripper, due to its advantages of easy deployment and plug and play, is suitable for applications that do not require high speed and tempo but require high mobility. The working principle is essentially through an energy - electromotive force - kinetic energy - speed change energy conversion process, which always needs motor, reducer and a series of devices to complete the complex conversion process, has to sacrifice efficiency and speed. The flexible gripper is the direct air drive (air pressure - clamping force), the air pressure directly drives the gripper, leaving out the middle link, more high-speed, efficient.

Flexible jaws VS cylinders

Image from the Internet

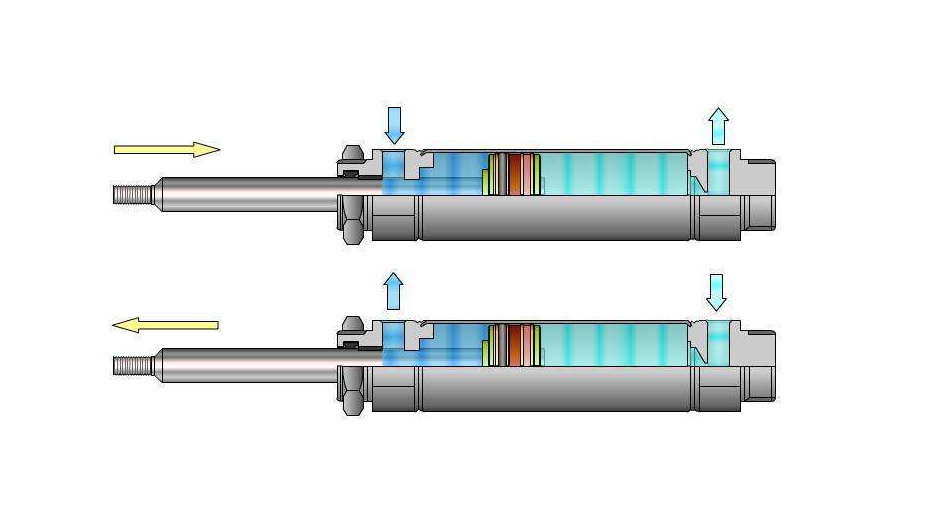

Cylinder products, driven by air pressure piston movement. The piston will create friction against the cylinder wall. Friction resistance will not only reduce the speed of the cylinder, a long time of high speed movement will also produce a lot of heat, resulting in the rapid aging of seals, affecting the service life.

The flexible claw will not produce any material friction in the process of working, so it avoids the wear and aging caused by friction and efficiency reduction, and the high-speed movement for a long time is as stable.

Therefore, speed comparison, only the vacuum chuck is the flexible claw of the same level of players.

Image from the Internet

So in the actual selection and installation, we should pay attention to what, in order to achieve high speed response?

Based on the working principle of the flexible jaws, it is not difficult to understand that to improve the opening and closing speed of the flexible jaws, essentially is to provide more flow on the jaws.

Therefore, to improve the opening and closing speed, you need to do:

1. Ensure sufficient and stable air source at the work site.

2 Use a high-traffic drive. PCU or iPCU high-speed drive is recommended. (Compared with the standard driver, the high-speed driver can improve the flow rate by 80% and the opening and closing speed by more than 50%).

3. Optimize the wiring of the trachea, and choose the trachea with shorter length and thicker diameter (ideal length < 2m, diameter ≥φ10mm) between the controller and the claw.

4 A drive with multiple fingers will also reduce the drive efficiency. Under the premise of satisfying the clamping force, you can choose to drive with multiple actuators or reduce the number of fingers.